High-Capacity Micropiles

Our Micropiles are capable of carrying 175+ Tons, they underpin foundations, enhance structure stability, transfer heavy loads and avoid underground utilities.

Micropile Overview

Micropiles, also known as minipiles, pin piles, and needle piles, are 3-10″ diameter friction or end bearing piles capable of carrying loads of 175 tons or more, however, 40-50 tons are most common.

- Ideal In Limited Access Areas

- Underpin Existing Structures

- Retrofit Foundations For Expansions

- May be Installed in Overburden Soils & Rock

- Load Capacities of 175+Tons

Micropile Installation Process

Typically, the micropile casing is advanced to the design-tip depth using specialized rotary drilling equipment and techniques. Once the tip depth has been achieved the casing is thoroughly flushed clean and a fully threaded, high strength, and centralized bar is inserted into the casing to full depth and the casing is fully grouted. After grouting, the casing can either be partially extracted, leaving the upper section cased and the bottom section bonded or the casing can be completely removed resulting in a fully-bonded or uncased micropile.

Types Of Micropiles

Uncased Micropiles

In tension/uplift applications the uncased pile, or fully bonded pile, is typically the micropile of choice. After grouting, the casing is completely removed leaving the high-strength cement grout and centralized threaded bar in place to interface directly with the soil or rock.

Features:

- Excellent Choice for Tension/Uplift Applications

Cased Micropiles

Features:

- Casing Provides Increased Axial, Lateral, and Buckling Load Capacity

- Ideal Where Soil Scouring is an Issue

Hollow Bar Micropiles

A hollow-bar micropile is comparable to an uncased micropile and can be used for both compression and tension loads. Uncased, these piles perform better in tension applications, however, a casing can be added to increase compression capacity. These piles do not require pre-drilling as the hollow-bar micropile is injected with neat cement grout and drilled simultaneously until the pile reaches design depth. Different sacrificial bits are used to accommodate any rock or soil type including hard rock, soft rock, and clay soils.

Features:

- Drill & Grout Simultaneously

- Works in Tension & Compression

- Casing May Be Added for Additional Compression Capacity

Helical Micropiles

Features:

- Instant Load Capacity – No Cure Time

- Typically a Cost-Effective Option for Lighter Loads

- Ideal for Temporary Support Such as Tilt Wall Bracing

- May Be Cased & Grouted for Increased Axial & Lateral Load Capacity

- Ideal for Underpinning Settling Structures

Typical Micropile Applications

Solutions:

- Underpinning Foundations

- Lifting Structures

- New Construction

- Deep Foundations

- Earth Retention

- Slope Stabilization

- Load Transfering

- Excavation Support

Typical Structures:

- Commercial Buildings

- Residential Buildings

- Condominium Buildings

- Railroads

- Bridges

- Outdoor Canopies

- Swimming Pools

- Airports

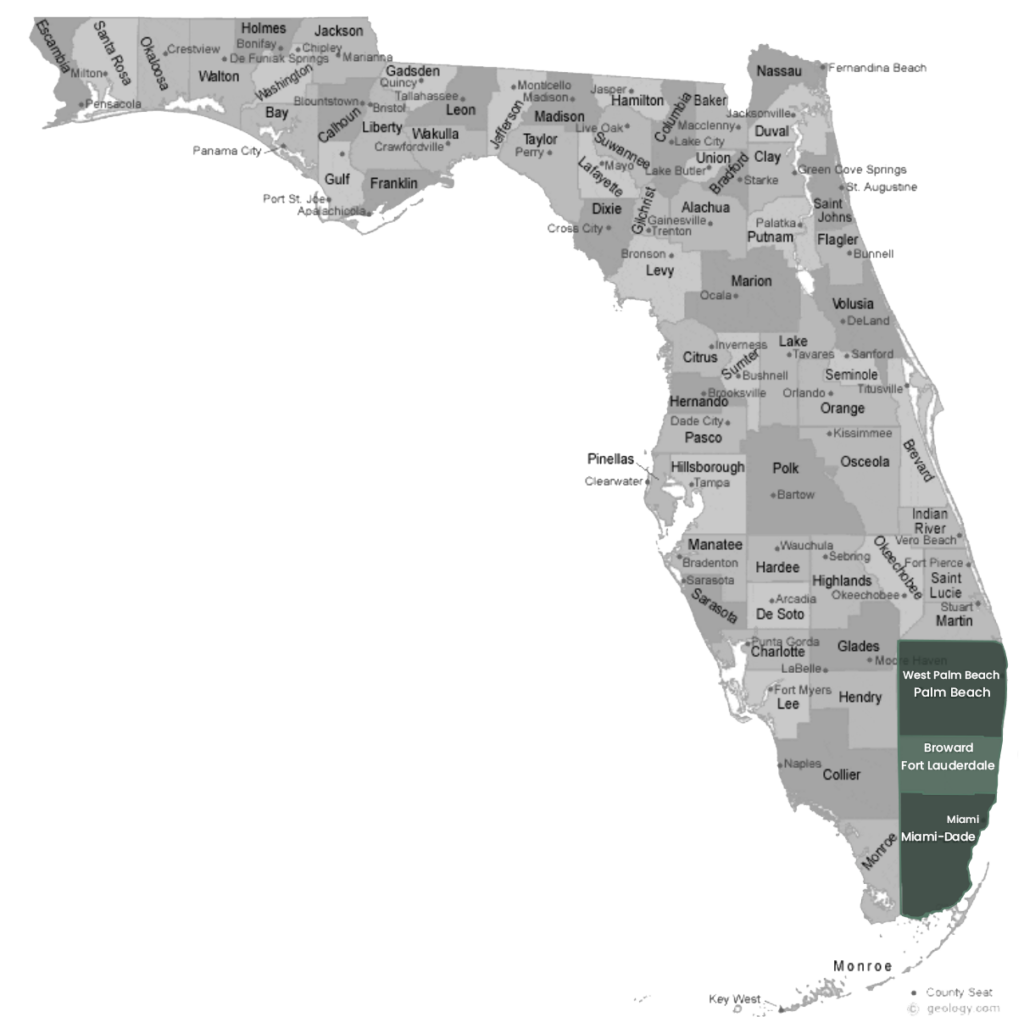

Service Area

At Dosdourian Enterprises Inc. we specialize in chemical grouting, helical piles, Waterstop and Foundation Repair in South Florida.

- Boca Raton, FL

- Boynton Beach, FL

- Deerfield Beach, FL

- Delray Beach, FL

- Palm Beach, FL

- Juno, FL

- Jupiter, FL

- West Palm Beach, FL